Prototyping plays a crucial role in the development of gun magazines, allowing manufacturers to test and refine designs before full-scale production. Various prototyping processes are utilized in the gun magazine industry, each with its own advantages and limitations. This article explores the different prototyping methods used in the industry and examines how they compare in terms of speed, cost, accuracy, material options, and suitability for different design complexities.

I. Types of Gun Magazine Prototyping Processes

- 3D Printing

- CNC Machining

- Injection Molding

- Handcrafted Prototypes

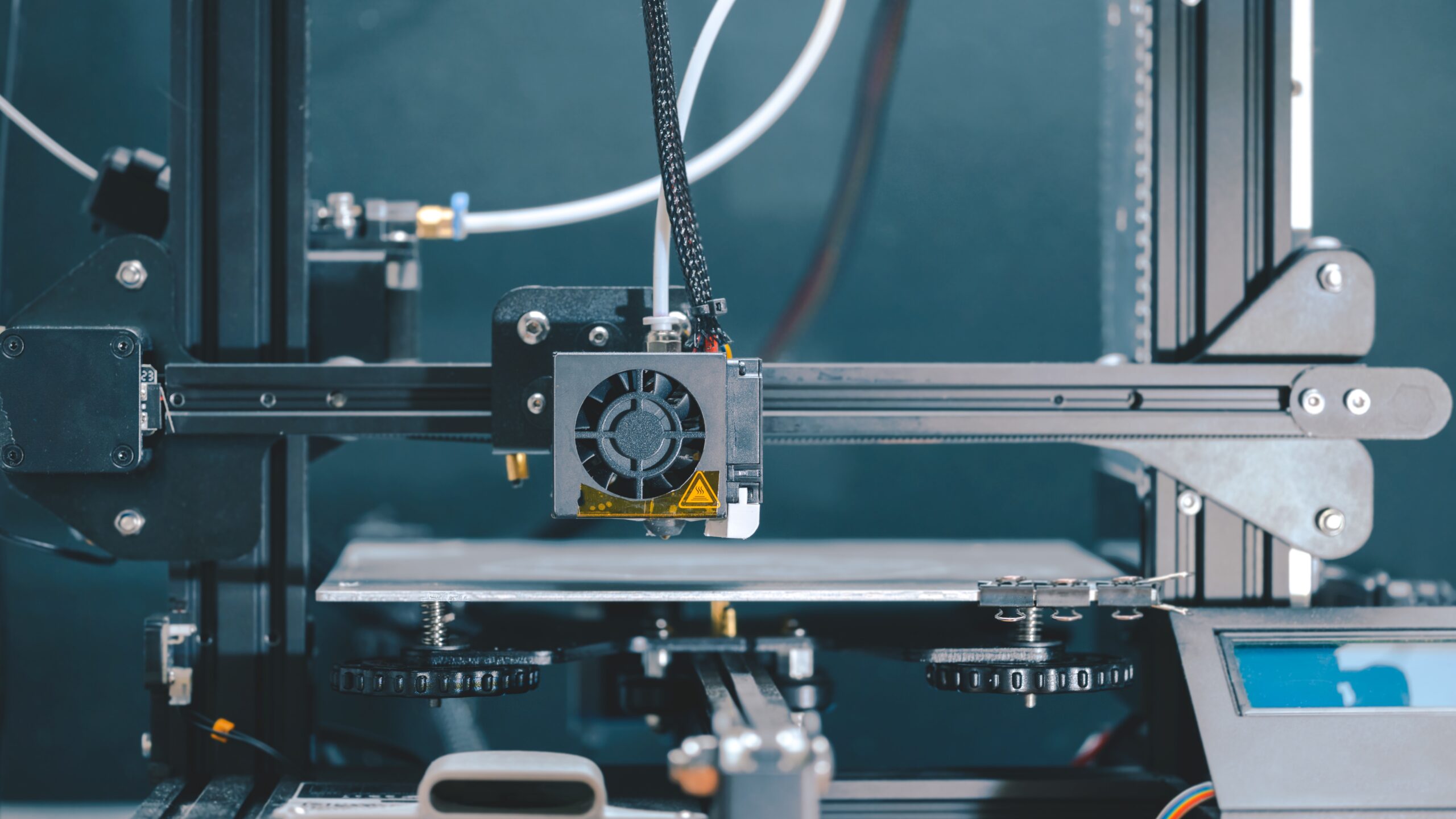

1. 3D Printing

3D printing, or additive manufacturing, stands out as a prominent prototyping method within the gun magazine industry. This process constructs three-dimensional objects layer by layer from a digital model, offering a range of advantages for manufacturers. One key benefit is rapid prototyping, enabling quick iteration and testing of various design concepts. This agility is particularly valuable for developing custom or specialized gun magazines where traditional manufacturing methods may be less flexible.

Cost-effectiveness is another significant advantage of 3D printing, especially for low-volume production runs. Traditional manufacturing processes often require expensive tooling and setup, making them less economical for producing small quantities of gun magazines. With 3D printing, manufacturers can produce prototypes and small batches without incurring substantial upfront costs, making it an attractive option for niche or specialized markets.

Additionally, 3D printing allows for the creation of complex geometries that would be challenging or impossible to achieve with traditional manufacturing methods. This capability opens up new possibilities for innovative gun magazine designs, such as intricate internal structures or ergonomic shapes optimized for performance and comfort.

However, it’s important to note that the quality of 3D-printed parts may not always match that of parts produced by traditional methods. The layer-by-layer nature of 3D printing can result in a slightly rough surface finish, and the material options are more limited compared to traditional manufacturing processes. These limitations may impact the durability and overall performance of 3D-printed gun magazines, particularly in high-stress or high-precision applications.

| Aspect | Advantages | Disadvantages |

| Rapid prototyping | – Allows for quick creation of prototypes. – Enables rapid testing of different design concepts. | – Surface roughness may occur. – Limited choice of materials. |

| Cost-effectiveness | – Particularly suitable for low-volume production. – Traditional manufacturing methods often require expensive tools and setups. | – Limited material selection compared to traditional methods. |

| Ability to produce complex geometries | – Can produce complex geometries that are difficult to achieve with traditional methods. – Provides possibilities for innovative designs. | – Surface roughness may occur. – Limited choice of materials. |

Examples of 3D printing applications in the gun magazine industry

- Rapid prototyping of new magazine designs for testing and evaluation.

- Iteration on designs based on feedback and performance testing.

- Production of custom or specialized gun magazines tailored to specific firearms or user requirements.

- Cost-effectiveness and practicality compared to traditional manufacturing methods.

In summary, while 3D printing offers significant advantages in terms of rapid prototyping, cost-effectiveness for low-volume production, and the ability to produce complex geometries, it also has limitations in terms of part quality and material options. Manufacturers must carefully evaluate these factors when choosing a prototyping method for gun magazine development, weighing the benefits of 3D printing against its potential limitations.

2. CNC machining

CNC machining, or computer numerical control machining, is a subtractive manufacturing process widely employed in the production of gun magazines, particularly for prototyping purposes. This method utilizes computer-controlled machines to precisely remove material from a solid block, creating intricate and precise parts with tight tolerances.

One of the primary advantages of CNC machining is its unparalleled accuracy, making it ideal for producing gun magazine prototypes that require precise dimensions and complex geometries. This accuracy ensures that the final product meets the exact specifications required for proper functioning within firearms. However, despite its precision, CNC machining can be relatively expensive and time-consuming compared to other prototyping methods. The process involves the creation of a custom toolpath for each part, which can result in longer lead times and increased costs, especially for low-volume production runs.

Despite these drawbacks, CNC machining remains a preferred method for prototyping gun magazines due to its ability to deliver high-quality, precise parts that meet the demanding requirements of the firearms industry.

| Aspect | Advantages | Disadvantages |

| Accuracy | – Unparalleled accuracy ensures precise dimensions and complex geometries, ideal for gun magazine prototypes. | – Relatively expensive and time-consuming compared to other prototyping methods. |

| Customization | – Allows for customization of magazine designs to meet specific firearm models or user preferences. | – Creation of custom toolpaths for each part can result in longer lead times and increased costs, especially for low-volume production runs. |

| Quality | – Delivers high-quality, precise parts that meet the demanding requirements of the firearms industry. | – Costs can be prohibitive for small-scale projects or individuals. |

| Functionality | – Ensures that the final product meets exact specifications required for proper functioning within firearms. | – Requires skilled operators and specialized equipment. |

| Versatility | – Versatile enough to produce a wide range of magazine components, from bodies and followers to springs and feed ramps. | – Limited material options compared to additive manufacturing methods like 3D printing. |

| Reliability | – Reliable and consistent results ensure consistent performance and reliability in gun magazines. | – Setup and programming time may be required for each new project, increasing lead times. |

| Industry Standards | – Compliant with industry standards and regulations for firearm components. | – Initial investment in CNC machines and tooling can be substantial. |

Examples of CNC Machining Applications in Gun Magazine Prototyping

- Creation of magazine bodies with intricate internal and external features for optimal functionality and aesthetics.

- Production of magazine followers and springs with precise dimensions to ensure proper feeding and reliability.

- Machining of magazine lips and feed ramps to ensure smooth and reliable ammunition feeding.

- Customization of magazine designs to accommodate specific firearm models or user preferences.

- Production of prototypes for testing and evaluation to ensure compatibility, functionality, and reliability.

In conclusion, CNC machining is a highly effective prototyping method in the gun magazine industry, known for its exceptional precision and ability to produce complex parts with tight tolerances. While it may be more expensive and time-consuming compared to other methods, its ability to deliver high-quality, custom parts makes it an ideal choice for producing prototypes that meet the stringent requirements of the firearms industry. As technology advances, CNC machining continues to play a crucial role in the development of innovative and reliable gun magazines.

3. Injection Molding

Injection molding is a versatile manufacturing process utilized in the gun magazine industry for its capability to produce high-quality parts with precise details. This process involves injecting molten material, typically plastic, into a mold cavity where it cools and solidifies to form the desired shape. While injection molding is commonly associated with mass production due to its efficiency in producing large quantities of parts, it is also applicable for prototyping purposes.

One of the key advantages of injection molding is its ability to achieve high levels of accuracy and intricacy in the produced parts. This is particularly beneficial in the gun magazine industry, where components must meet strict specifications for proper functionality and compatibility with firearms. Additionally, injection molding offers excellent surface finish, which is important for parts that require smooth and uniform surfaces for optimal performance.

Another advantage of injection molding is the wide range of materials that can be used. This includes various types of plastics, such as ABS, polycarbonate, and nylon, which offer different properties such as strength, durability, and chemical resistance. This flexibility in material selection allows manufacturers to choose the most suitable material for the specific requirements of the gun magazine, ensuring that the final product meets the desired performance standards.

Despite its advantages, injection molding has some limitations. One of the main drawbacks is the high cost and time involved in setting up the molds. This makes injection molding less suitable for low-volume production or rapid gun magazine prototyping, where cost-effectiveness and quick turnaround are essential. Additionally, the initial investment required for mold creation and setup can be significant, especially for complex designs or specialized materials.

| Aspect | Advantages | Disadvantages |

| Accuracy | Achieves high levels of accuracy and intricacy in produced parts | High cost and time involved in setting up molds |

| Surface Finish | Offers excellent surface finish, crucial for parts requiring smooth and uniform surfaces | Less suitable for low-volume production or rapid prototyping |

| Material Selection | Wide range of materials available, including plastics with different properties | Initial investment for mold creation and setup can be significant, especially for complex designs or specialized materials |

Examples of Injection Molding Applications in Gun Magazine Prototyping

- Production of gun magazine bodies with precise dimensions and smooth surfaces for optimal functionality.

- Creation of magazine followers and baseplates to ensure proper feeding and easy handling.

- Manufacturing of magazine springs and floor plates for reliable operation and durability.

- Prototyping of custom-designed magazine accessories, such as extended baseplates or finger rests.

- Development of specialized magazine components for compatibility with specific firearm models or applications.

Overall, injection molding is a valuable gun magazine prototyping method in the gun magazine industry, offering high accuracy, excellent surface finish, and material versatility. While it may not be suitable for all prototyping needs, its ability to produce high-quality parts makes it a preferred choice for manufacturers seeking to develop reliable and functional gun magazines.

4. Handcrafted Prototypes

Handcrafted prototypes in the gun magazine industry are meticulously crafted by skilled artisans using traditional tools and techniques. This method, although time-consuming and labor-intensive, offers a unique level of customization and attention to detail that is unmatched by automated processes. Handcrafted prototypes are often sought after for their artisanal quality and are typically used for one-off or low-volume production where the cost of other prototyping methods is prohibitive.

One of the key advantages of handcrafted prototypes is the ability to achieve intricate and unique designs that may be challenging or costly to produce using automated methods. Artisans can work closely with designers and engineers to bring complex concepts to life, ensuring that each prototype is tailored to meet specific requirements. Additionally, handcrafted prototypes allow for quick adjustments and modifications during the prototyping process, enabling designers to refine their designs based on real-world testing and feedback.

Despite their advantages, handcrafted prototypes also have limitations. They are inherently less precise and consistent compared to parts produced by modern manufacturing methods. This can result in slight variations in dimensions and aesthetics between individual prototypes, which may not be suitable for applications requiring high levels of uniformity. Additionally, the labor-intensive nature of handcrafting can lead to higher costs and longer lead times, making this method less practical for large-scale production.

| Aspect | Advantages | Disadvantages |

| Customization | 1. Allows for intricate and unique designs 2. Tailored to meet specific requirements 3. Artisans can work closely with designers and engineers | 1. Time-consuming and labor-intensive 2. May not be suitable for high-volume production 3. Cost-prohibitive for large-scale manufacturing |

| Attention to Detail | 1. Offers a high level of attention to detail 2. Enables quick adjustments and modifications during the prototyping process | 1. Less precise and consistent compared to parts produced by modern methods 2. Variations in dimensions and aesthetics between individual prototypes 3. Not suitable for applications requiring high levels of uniformity |

| Quality | 1. Sought after for artisanal quality 2. Provides a unique and handcrafted feel 3.Can result in high-quality prototypes | 1. Labor-intensive nature leads to higher costs 2.Longer lead times 3.Less practical for large-scale production |

Examples of Handcrafted Prototypes Applications in Gun Magazine Prototyping

- Handcrafted wooden gun magazine prototype carved from a solid block of wood to showcase the design and ergonomics.

- Handcrafted metal gun magazine prototype fabricated using traditional metalworking techniques such as milling, turning, and welding.

- Hand-stitched leather gun magazine prototype featuring intricate designs and patterns for a unique aesthetic appeal.

- Hand-molded polymer gun magazine prototype formed using molding and shaping techniques for a custom fit and finish.

- Hand-painted gun magazine prototype showcasing different color schemes and finishes for visual evaluation and customization options.

- Hand-assembled gun magazine prototype with carefully selected components to test functionality and ease of assembly.

- Hand-carved foam gun magazine prototype for ergonomic evaluation and design refinement before final production.

Overall, handcrafted prototypes play a valuable role in the gun magazine industry, offering a level of craftsmanship and customization that cannot be replicated by automated processes. While they may not be suitable for all applications, they remain a valuable tool for designers and manufacturers looking to create unique and high-quality prototypes.

II. Comparison of Gun Magazine Prototyping Processes

| Aspect | 3D Printing | CNC Machining | Injection Molding | Handcrafted Prototypes |

| Speed | Rapid | Moderate | Slow | Slow |

| Cost | Low | High | High | Moderate |

| Accuracy | Moderate | High | High | Variable |

| Material Options | Limited | Wide range | Wide range | Limited |

| Complexity | Good for complex | Good for complex | Good for complex | Good for complex |

III. Factors to Consider When Choosing a Gun Magazine Prototyping Process

When selecting a prototyping process for gun magazines, several factors should be considered to ensure the chosen method meets the specific requirements of the project. These factors include:

| Aspect | Consideration | Example |

| Accuracy and Precision | The process should be capable of producing parts with the required level of accuracy and precision. | CNC machining is known for its high precision and ability to produce parts with tight tolerances. |

| Material Properties | Consider material options and their properties such as strength, durability, and compatibility with firearms. | Different plastics used in injection molding offer varying properties suitable for gun magazine applications. |

| Cost-Effectiveness | The overall cost of prototyping should be considered, especially for low-volume production or one-off prototypes. | Handcrafted prototypes, while labor-intensive, may be more cost-effective for one-off or low-volume production compared to CNC machining. |

| Speed of Production | The time required to produce prototypes can impact the development timeline. Methods offering rapid prototyping capabilities are desirable. | 3D printing is known for its rapid gun magazine prototyping capabilities, allowing for quick iteration on designs. |

| Complexity of Geometry | Some methods are better suited for producing parts with complex geometries than others. | 3D printing excels at producing parts with complex geometries, making it suitable for intricate gun magazine designs. |

| Surface Finish | The surface finish of the prototype can affect its aesthetics and functionality. | CNC machining offers excellent surface finish, which is important for parts requiring smooth and uniform surfaces. |

| Volume of Production | Consider the volume of prototypes needed, as some methods are better suited for producing large quantities of parts than others. | Injection molding is suitable for high-volume production, making it ideal for mass-producing gun magazine components. |

| Post-Processing | Depending on the method used, post-processing steps such as painting, polishing, or assembly may be required. | Handcrafted prototypes may require post-processing steps to achieve the desired finish and functionality. |

| Environmental Impact | Some prototyping methods may have a larger environmental impact than others. Consider the sustainability of the chosen method. | 3D printing, when using biodegradable materials, may have a lower environmental impact compared to other methods. |

| Regulatory Compliance | Ensure that the chosen prototyping method complies with relevant regulations and standards for firearm components. | All gun magazine prototyping methods must comply with firearm regulations to ensure the safety and legality of the final product. |

IV. Conclusion

The variety of gun magazine prototyping processes available offers manufacturers a range of options to explore. Each method has its strengths and weaknesses, making it crucial for manufacturers to carefully consider their specific needs and requirements when choosing a gun magazine prototyping process.

Recap of Key Points

- 3D Printing: Ideal for rapid prototyping and complex geometries, but may lack durability for certain applications.

- CNC Machining: Offers high precision and tight tolerances, suitable for parts requiring accuracy and compatibility.

- Injection Molding: Cost-effective for mass production, providing a wide range of material options, but may be less suitable for low-volume production or rapid prototyping.

- Handcrafted Prototypes: Offer a unique level of customization and attention to detail, but are labor-intensive and less precise compared to automated methods.

Encouragement for Manufacturers

Manufacturers are encouraged to explore different gun magazine prototyping methods to enhance product development, foster innovation, and improve cost-effectiveness. By understanding the advantages and limitations of each process, manufacturers can make informed decisions that lead to the creation of high-quality gun magazines that meet the demands of the market.

Example Scenario

For example, a manufacturer developing a new line of high-capacity pistol magazines may choose to use 3D printing for initial prototypes to quickly iterate on design concepts. Once the design is finalized, they may opt for CNC machining to create precision-engineered molds for injection molding, ensuring mass production meets the required specifications.

Innovation and Flexibility

By embracing innovation and remaining flexible in their approach to gun magazine prototyping, manufacturers can stay ahead of the competition and deliver superior products to their customers. Whether aiming for mass production efficiency or customized solutions, the right prototyping process can make all the difference in achieving success in the gun magazine industry.